Beer Tap Systems for Breweries & Bars

Brewmasters, Brewers, and Their Beer Tap Systems

It’s not always easy to please the person who makes this industry function – the brewmaster. The brewmaster is responsible for all things related to making beer, including selecting ingredients. They the main people responsible for preparing beer mixtures, creating beer recipes, and overseeing the entire fermenting process. They are passionate about their business and have the highest standards when it comes to the beer tap systems used to make and pour their beer. We love this about them as we are just as passionate about making sure that their beer is poured to their high standards when it leaves their brewery.

Brewers, on the other hand, support the brewmasters and head brewers with anything they need. This title encompasses many different tasks. Generally, the brewer answers to the brewmaster, however there are rare instances where the brewer might report to someone different. Brewers have the ability to work in the brewhouse, the cellar, or the packing department.

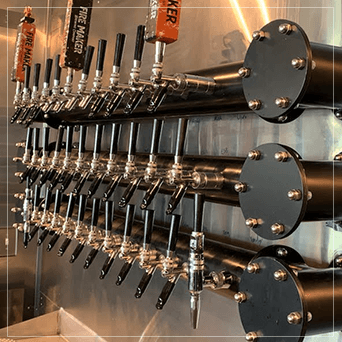

Featured ProjectRendezvous Junction

The phenomenon of friends coming together (rendezvous) at a place (junction) to enjoy great-tasting beer was the inspiration behind their brand name.

When considering how beer tap systems work, you’ll hear them referred to as short-draw or long-draw.

Short-Draw or Direct Draw Beer System

Direct draw systems are the most typical and direct way to dispense beer from walk-in cooler systems or self-contained keg storage to a tap when the two are close together. Short-draw is the go-to for many businesses, bars or restaurants. Each draft beer faucet is connected to a cooled box tower directly linked to its own self-contained cooler.

Air-cooled systems remain a cost-effective option for short-draw systems. They work by circulating cold air from a walk-in cooler to remote faucets, cooling kegs, beer lines, and towers along the way. A temperature-regulated blower fan inside the walk-in cooler efficiently cools the trunk lines. Smaller flexible tubing houses the trunk line and is encased in larger, insulated metal tubing to prevent heat transfer from outside elements. Cold air flows through this system directly to your beer tower’s faucets, ensuring refreshingly cool drinks. These reliable units are still prevalent in many establishments – providing patrons with cold drinks without breaking budgets or sacrificing performance.

Direct draw beer systems connected with walk-in cooler systems work efficiently and cost-effectively to store, serve, and access kegs. This combination is a convenient solution for pouring commercial beer at the same temperature as the walk-in. With proper setup and maintenance, this system can be highly beneficial for any draft beer dispensing business!

Long-Draw or Glycol-Cooled Remote Beer System

This system ensures the walk-in cooler temperature remains consistent and allows the cold beer to be delivered over great distances. The coolant lines take on the chilly temperatures from within the fridge and deliver them with constancy directly to your serving tower. This draft beer dispensing system allows your customers to always enjoy a perfectly chilled beverage!

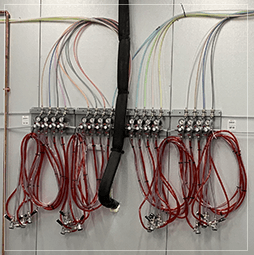

This trunk housing is specially designed to transport commercial beer up to 1,000 feet while remaining at optimal chill temperatures. Temperature control can always be achieved thanks to factors such as vapor barrier foil tape, insulation, and modern coolant lines. The glycol power pack ensures beer is kept at an ideal temperature by refrigerating and circulating glycol coolant from a walk-in cooler through supply beer lines to behind each faucet’s tower, then returning for cooling. This continual cycle keeps beverages icy cold at a bar or restaurant.

Long draw systems are incredibly flexible, allowing for varied custom designs. With the right design and installation, you can expect your long-draw system to provide years of beer pours that will translate directly into profits!

Frequently Asked Questions About Beer Tap Systems

What are some of the pros of a standard-type faucet for a beer tap system? The standard faucet heads are the most used faucet, so they are tried and true and designed to dispense many different styles of beer. They also come in a wide range of sizes, shapes, and finishes to suit your establishment’s style.

What does “flow control” mean in beer tap systems? Flow control lets you adjust the flow of the beer from the tap, which is useful when serving different beer styles from one pressure source.

What is the difference between a European faucet and a standard faucet head? You’ll notice that a European faucet head on a beer tap system is a thinner and longer spout than the standard faucet. This causes the foam head in pours to be smaller.

How can a beer tap system be self-closing? Self-closing taps are like standard faucets but have a spring that lets them quickly and completely close to prevent the loss of any beer.

Why do some beer tap systems use roto tap faucet heads? Rototaps are European-style faucets and their fewer parts make them easier to clean. They also keep bacteria out of tap lines thanks to their tapered design.

What is a direct draw beer tap system? They are the most common beer tap systems because they are customizable enough to suit any business’s needs. The kegs are stored in a beer cooler when this type of beer dispenser is used. As well as being one of the most popular beer systems, this one is also very easy to use. The system is simple and effective, exactly what we would recommend to someone opening a bar or restaurant. When it comes to cleaning the beer lines, this is also one of the least costly beer systems.

What makes a stout faucet head special in a beer tap system? They are used for any nitro beers, allowing for the classic cascading effect which produces a rich, creamy head. The restrictor plate forces the beer through tiny holes that agitates the nitrogen, breaking it out of solution and providing a great visual as the beer settles.